Building a Connected Machine Ecosystem: Industrial IoT and AI for Smart Factories

- by Indu Sharma

Walk into a modern factory today, and you’ll notice something different—it’s not just machines doing their job. It’s machines talking to each other, adjusting on the fly, predicting problems before they happen, and even helping teams make better decisions. What’s driving this big shift? A combination of the connected machine ecosystem IoT and powerful artificial intelligence (AI).

In short, smart factories aren’t just the future anymore—they’re happening right now.

So, What Exactly Is a Connected Machine Ecosystem?

Imagine every machine on your shop floor could talk to the next one. Not with wires and blinking lights—but by sharing real-time data, making small decisions, and working together to keep things running smoothly. That’s a connected machine ecosystem

Using industrial IoT (Internet of Things) tech, machines, sensors, and systems are connected in a way that lets them:

– Monitor themselves

-Share information in real time

-Predict when something’s going to break

-Adjust to new situations on the fly

This isn’t just about convenience, it’s about cutting downtime, boosting efficiency, and turning your factory into something more intelligent and agile.

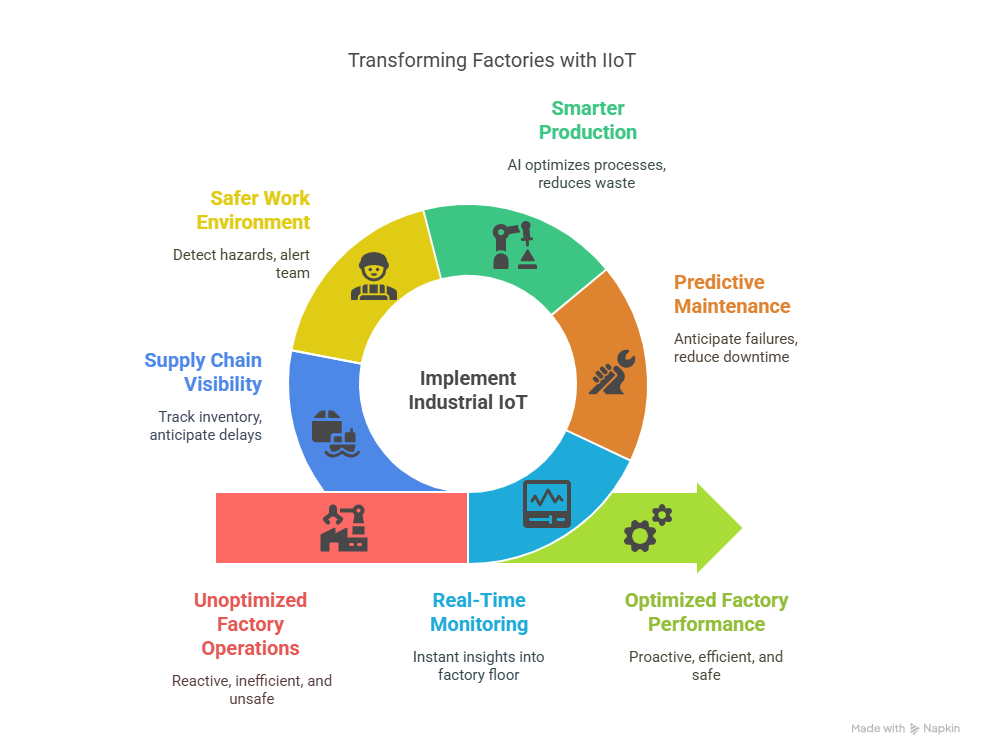

Why Industrial IoT Is a Game-Changer

The industrial internet of things isn’t just another buzzword. It’s changing how factories operate at every level. With IIoT, physical devices—from machines to tools are connected to software and data systems that help keep everything running like clockwork.

Here’s what that looks like in action:

Real-Time Monitoring- Know exactly what’s happening on your factory floor right now. No more waiting until the end of a shift or finding out too late that a machine overheated.

Predictive Maintenance- Instead of fixing something after it breaks, smart sensors tell you before there’s a problem. That means less downtime and lower maintenance costs.

Smarter Production- AI analyzes data across your machines and can suggest how to fine-tune schedules, optimize processes, and cut down on material waste.

Safer Work Environment- Wearables and smart sensors can detect unsafe temperatures, poor air quality, or even worker fatigue and alert the team before things get dangerous.

Supply Chain Visibility – With IIoT, you know what inventory you have, what’s on the way, and where delays might happen so you can act fast and plan better.

How AI Makes the Ecosystem Even Smarter

Connecting machines is step one. But the real magic happens when you bring in AI.

Think of AI as the brain of your connected machine ecosystem. It takes all the raw data from your machines and turns it into useful insights you can act on.

Here’s how AI adds value:

– It sees patterns in machine data and can help reduce energy use.

– It powers computer vision tools that inspect products for defects in real time.

– It learns from past events, like machine failures, and helps you avoid them in the future.

When AI and industrial IoT work together, your factory becomes more than efficient—it becomes smart, self-learning, and ready for anything.

What This Looks Like in the Real World

Let’s break down how different industries are already using this tech:

Automotive- Sensors and cameras monitor the entire assembly line, spotting issues in real time. This means better quality cars and fewer production delays.

Pharmaceuticals – In cleanroom environments, IIoT devices constantly track air quality, temperature, and humidity, keeping medicine safe and compliant.

Food & Beverage- AI systems adjust cooking times, monitor hygiene conditions, and ensure every product meets the same high standard, batch after batch.

Textile- High-speed machines don’t wait for humans to detect problems. Predictive maintenance keeps everything humming smoothly.

No matter the industry, smart factories powered by the connected machine ecosystem IoT are proving to be faster, safer, and more reliable.

But Let’s Be Real – There Are Challenges Too

This transformation doesn’t happen overnight. There are some real hurdles:

High Upfront Costs: Smart devices, sensors, and platforms can be expensive at first.

Cybersecurity Concerns: More connectivity means more exposure, so protecting your data is critical.

Skill Gaps: Not every team has the expertise to run or maintain IIoT and AI systems.

Old Machines: Legacy systems may not be easy to integrate without extra work.

But the good news? These challenges can be tackled with the right guidance, training, and planning. And that’s where partners like us come in.

How Value Innovation Labs Helps You Build Smarter

At Value Innovation Labs, we help manufacturers move from traditional setups to future-ready smart factories.

We don’t just sell tech—we build solutions that fit your operations, your team, and your goals.

Our services include:

- Crafting your IIoT and connected machine strategy

- Connecting machines and systems across your factory

- Integrating AI tools that drive real-time insights

- Enabling fast, edge-based decisions (without needing to send everything to the cloud)

- Keeping your systems secure and compliant

Whether you’re just starting out or scaling up, we’re here to help you do it the right way step by step.

What’s Coming Next?

-The pace of change isn’t slowing down. In the near future, you’ll see even more exciting developments like:

-AI at the edge: Making real-time decisions without needing to connect to a central server

-Cloud-integrated manufacturing: Run your entire operation with visibility from anywhere

-Blockchain: Full transparency and traceability for every product-Digital twins: Virtual models of your operations that you can test, improve, and perfect before going live

And guess what? All of this still revolves around the same idea, a connected machine ecosystem IoT that brings everything together.

Conclusion

This Isn’t Just a Tech Upgrade, It’s a Shift in Mindset

Moving toward a smart factory isn’t just about buying new machines or software. It’s about changing how your business thinks, operates, and evolves. It’s about using data to make smarter choices, solve problems before they grow, and keep your team safe and efficient.

The industrial internet of things, combined with AI, gives manufacturers a way to work smarter, not just harder.

At Value Innovation Labs, we’re ready to help you take that leap, whether you’re exploring the possibilities or building your ecosystem from the ground up. The future is connected, intelligent, and adaptable. And it starts with one smart decision.

Walk into a modern factory today, and you’ll notice something different—it’s not just machines doing their job. It’s machines talking…