AI Powered Quality Control: Enhancing Manufacturing Excellence

- by Indu Sharma

In today’s competitive manufacturing world, quality isn’t just a checkbox it’s everything. One small defect could cost you a loyal customer, delay a shipment, or damage your brand. And let’s face it: relying only on manual quality checks just doesn’t cut it anymore.

They’re slow. They’re inconsistent. And they’re expensive.

That’s where AI-powered quality control in manufacturing is making a real difference—especially for businesses in the private sector. With smart cameras, machine learning, and instant insights, AI helps you catch defects early, improve processes, and deliver top-notch products, every single time.

Let’s break it down simply, clearly, and from a human point of view.

What Is AI Quality Control in Manufacturing?

Imagine having a super-inspector on your team someone who can spot even the tiniest defect, never gets tired, and keeps learning every day. That’s what AI quality control in manufacturing brings to the table.

It uses smart technologies like machine learning, sensors, and computer vision to check each product in real time as it moves along your production line. Instead of just sampling a few items, AI checks everything—fast, accurately, and without breaks.

Why Manual Quality Control Isn’t Enough

If your process still depends entirely on people, you’re not alone. But here are a few hard truths:

- People get tired and distracted

- Manual checks slow down production

- Mistakes happen, especially on fast lines

- Quality can vary from one shift to another

- And yes—it adds to your costs

Your customers expect perfect products, and your reputation depends on meeting that expectation every time.

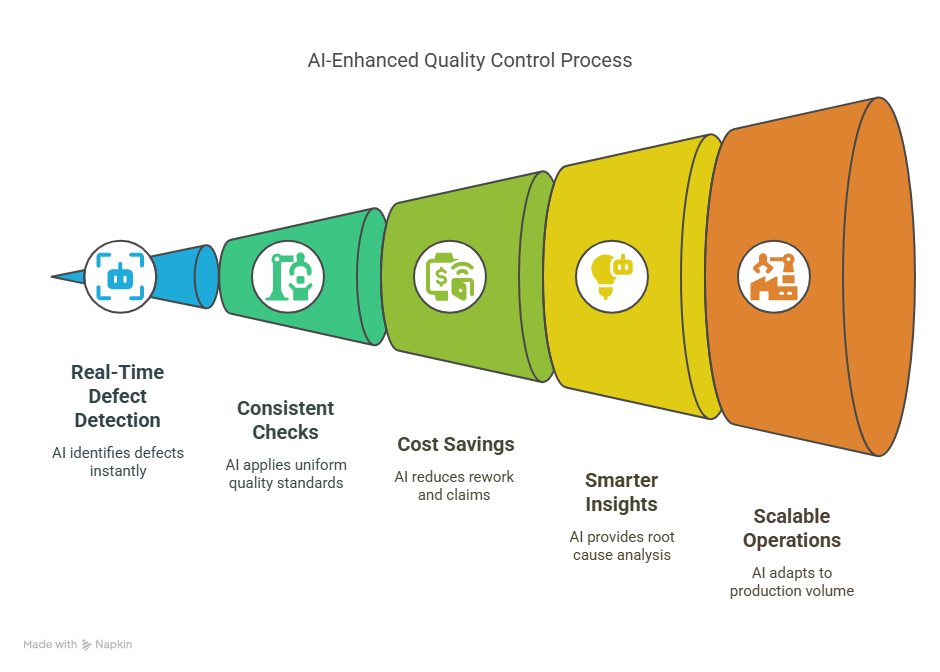

How AI Improves Quality Control

Here’s where AI steps in and turns quality assurance into a superpower:

- Real-Time Defect Detection – AI-powered cameras catch scratches, misalignments, wrong colors, missing parts, anything that’s not up to your standard instantly.

- Consistent and Objective Checks – No fatigue. No guesswork. AI applies the same quality rules to every item, no matter the hour or shift.

- Cost Savings – AI helps you avoid costly reworks, warranty claims, and customer complaints. Over time, it pays for itself.

- Smarter Insights – It doesn’t just tell you something’s wrong, it helps you understand why. That’s how real improvements happen.

- Built to Scale – Whether you’re making 500 items or 50,000, AI scales with your business. No need to constantly hire more inspectors.

Where It’s Working: Private Sector Success Stories

Companies across India’s private sector are already seeing results with AI:

- Automotive – Identifying faulty welds or off-color paint in real-time

- Pharma – Making sure pills are the right size, color, and properly packaged

- FMCG – Checking labels, seals, barcodes, and expiry dates

- Electronics – Spotting micro-cracks, soldering issues, and component mismatches

AI is helping these businesses stay competitive and trusted.

What Powers AI-Based Quality Control?

AI isn’t magic, it’s powered by smart, accessible technology:

- Machine Learning: Learns from your data to recognize patterns and detect issues better over time

- Computer Vision: Smart cameras scan products in milliseconds and flag visual defects

- Edge Computing: Data is processed instantly on the factory floor, not sent to the cloud

- Predictive Analytics: AI can even forecast future issues before they happen

Common Concerns (And Real Answers)

Is AI too expensive for us?

Nope. Today’s AI solutions are more affordable than ever. You can start small and grow as you see the results.

Will it replace my team?

Absolutely not. AI supports your team by handling repetitive tasks—your people can focus on problem-solving and process improvement.

Will it disrupt my operations?

With the right partner (that’s us!), setup is smooth and designed to fit into your existing workflow without causing downtime.

Why Private Sector Manufacturers Shouldn’t Wait

If you run a small or medium-sized business, you probably face:

- Tighter deadlines

- Leaner teams

- High customer expectations

This is where AI shines. It helps you do more with less, improve product quality, and grow your business confidently.

You don’t need to be a tech giant to use AI—you just need the right guidance and tools.

How We Help at Value Innovation Labs

At Value Innovation Labs, we make AI simple, practical, and useful. We don’t throw buzzwords at you, we build real solutions that work for your business.

Here’s what we do:

- Analyze your current QC system

- Identify AI opportunities

- Deploy AI-powered vision tools

- Train AI models for your specific products

- Set up real-time alerts and performance dashboards

- Provide support every step of the way

Whether you’re just exploring AI or ready to dive in, we’ve got your back.

Final Thoughts

Let’s be real your customers expect flawless products. You want to meet that expectation without burning time, money, or your team out.

AI quality control in manufacturing helps you do just that. It gives you speed, accuracy, and confidence, so you can focus on growing your business and building a reputation for excellence.

If you’re in the private sector and ready to take quality seriously, now is the perfect time to explore what AI can do for you.At Value Innovation Labs, we make AI work for real manufacturers with real challenges. Let’s chat and see how we can help you build a smarter, better production line together.

Frequently Asked Questions

Q1: Is AI-based quality control only for large manufacturers?

Nope. Small and medium businesses are leading adopters because AI helps them compete with larger players.

Q2: How accurate is AI in quality control?

AI can reach 98–99% accuracy, often better than human inspection, especially over long shifts.

Q3: What types of issues can AI detect?

Scratches, dents, misalignments, incorrect labels, and packaging issues, if it’s visible, AI can usually catch it.

Q4: Isn’t AI too complex for small businesses?

Not with the right partner. We tailor AI tools to fit your team, your machines, and your budget.

In today’s competitive manufacturing world, quality isn’t just a checkbox it’s everything. One small defect could cost you a loyal…