How AI-Powered Predictive Maintenance Reduces Downtime and Costs in Manufacturing

- by Indu Sharma

In the fast-paced world of manufacturing, time is money. Every minute of unplanned downtime can lead to lost productivity, missed deadlines, and ultimately, financial loss. That’s why more manufacturers are now turning to AI predictive maintenance in manufacturing to keep their operations running smoothly, reduce costs, and improve efficiency.

Rather than reacting to equipment failures after they happen, predictive maintenance uses AI and data analytics to anticipate issues before they disrupt production. The result? Less downtime, lower maintenance costs, and a smarter, more proactive way of working.

In this blog, we’ll explore how AI-powered predictive maintenance is revolutionizing the industry and why it’s quickly becoming a must-have tool for manufacturers.

What is AI Predictive Maintenance in Manufacturing?

AI predictive maintenance is a smart maintenance strategy that uses machine learning, sensors, and historical data to predict when machinery might fail. Instead of waiting for a breakdown, manufacturers can fix problems before they escalate, saving time and money.

These AI systems continuously monitor machinery performance, analyze vibration, temperature, and noise levels, and detect patterns that signal potential problems. Once an anomaly is detected, it can trigger alerts and suggest maintenance actions, reducing unexpected breakdowns.

Why Traditional Maintenance Isn’t Enough

Traditional maintenance falls into two main categories:

Reactive maintenance: Fixing equipment after it breaks down.

Preventive maintenance: Servicing equipment at scheduled intervals, regardless of its condition.

Both methods have limitations:

Reactive maintenance often leads to costly downtime and emergency repairs.

Preventive maintenance can be inefficient, leading to unnecessary servicing and wasted resources.

With AI-powered predictive maintenance, manufacturers can strike the perfect balance, servicing equipment only when needed, based on real-time data and insights.

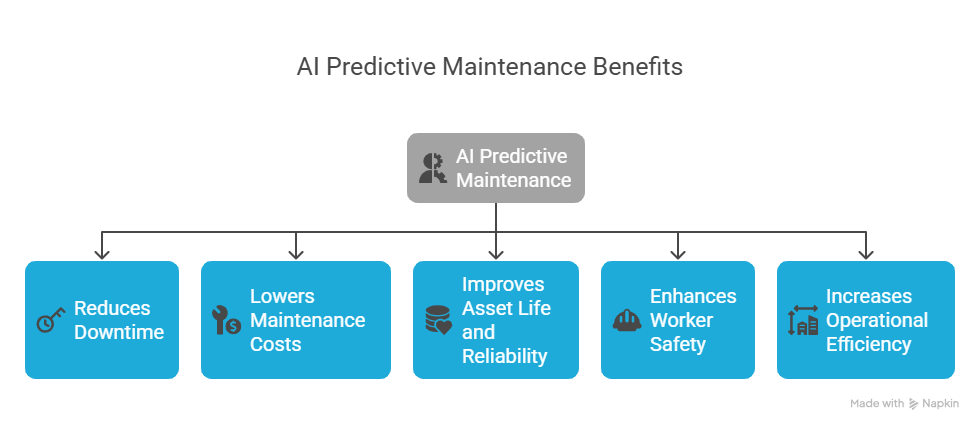

Key Benefits of AI Predictive Maintenance

Let’s dive into how AI predictive maintenance in manufacturing delivers real business value:

-

Reduces Downtime

The biggest advantage is minimizing unplanned equipment failures. Predictive systems alert teams before a machine fails, allowing timely repairs and avoiding production stoppages. This boosts uptime and keeps operations running.

-

Lowers Maintenance Costs

With predictive maintenance, you’re no longer wasting time and money on unnecessary servicing. You fix what needs fixing, when it needs fixing, saving on labor, parts, and resources.

-

Improves Asset Life and Reliability

By identifying issues early, AI helps prevent severe damage to equipment. This extends the lifespan of machinery and improves overall reliability.

-

Enhances Worker Safety

Equipment failures can be dangerous. Predictive systems reduce the risk of accidents caused by sudden malfunctions, creating a safer workplace.

-

Increases Operational Efficiency

Smart scheduling, fewer disruptions, and better use of resources all contribute to a more efficient manufacturing process.

How Predictive Maintenance Works

AI-driven predictive maintenance uses a mix of technologies to deliver insights:

- IoT Sensors continuously collect data on machine performance (vibration, temperature, noise, pressure, etc.).

- Machine Learning Algorithms analyze historical and real-time data to detect patterns and predict failures.

- Edge Computing processes data on-site for instant alerts and faster response.

- Cloud Platforms store and analyze large volumes of data for long-term trends and insights.

This multi-layered approach makes predictive maintenance scalable, accurate, and adaptable to different manufacturing environments.

Real-World Use Cases

Let’s look at how predictive maintenance is already helping manufacturers across sectors:

- Automotive – Identifying potential failures in robotics or conveyor belts before they halt production.

- Textile – Monitoring looms for early signs of bearing wear or overheating.

- Food Processing: Ensuring refrigeration units and packaging machines run efficiently to prevent spoilage.

- Electronics – Spotting micro-vibrations that signal tool misalignment in circuit board assembly.

In each case, the goal is clear: reduce predictive maintenance downtime, optimize production, and avoid last-minute chaos.

Why Manufacturers Are Investing Now

With growing pressure to stay competitive, manufacturers can’t afford long downtimes or inefficient operations. AI offers a solution that not only cuts costs but also boosts productivity and customer satisfaction.

Add to this the fact that sensor costs are falling and AI tools are more accessible than ever, and it’s easy to see why adoption is accelerating.

Getting Started with Predictive Maintenance

If you’re new to predictive maintenance, here’s a roadmap to help you begin:

- Identify critical assets where downtime has the most impact.

- Install sensors to collect performance data.

- Choose an AI platform that integrates with your current systems.

- Train the AI models using historical data and real-time feedback.

- Set alerts and protocols for responding to issues.

- Continuously refine the models as new data comes in.

Partnering with an expert solution provider like Value Innovation Labs can make this transition smoother. We help tailor the solution to your equipment, goals, and budget.

Common Challenges (And How to Overcome Them)

- Cost concerns – Start small. Focus on one or two critical machines, prove the ROI, and expand from there.

- Data overload – Use AI to filter the noise. The goal is actionable insights, not just data collection.

- Skill gaps – Train your existing staff or partner with experts. Predictive maintenance doesn’t require a complete team overhaul.

The Future is Predictive

Looking ahead, AI predictive maintenance will only grow more powerful. With advances in machine learning and edge computing, manufacturers will be able to:

- Predict failures with even greater accuracy

- Automate maintenance workflows

- Reduce maintenance-related emissions and waste

It’s not just about fixing machines, it’s about transforming your entire approach to manufacturing.

How Value Innovation Labs Can Help

At Value Innovation Labs, we specialize in helping manufacturers adopt enterprise-grade AI predictive maintenance solutions. From sensor setup to AI integration and ongoing support, we handle every step.

Our approach is tailored, scalable, and grounded in real-world manufacturing challenges. Whether you’re just getting started or scaling up, we’ll help you reduce predictive maintenance downtime and improve your bottom line.

Final Thoughts

AI predictive maintenance in manufacturing isn’t a trend, it’s the future. By reducing unplanned downtime and cutting costs, it empowers manufacturers to focus on growth, innovation, and delivering consistent value.

Ready to future-proof your operations? Let’s talk about how Value Innovation Labs can help you get there.

Frequently Asked Question

Q1: Is AI predictive maintenance only for large enterprises?

Not at all. Even small and mid-sized manufacturers are adopting it thanks to scalable and affordable solutions.

Q2: How soon can I see ROI?

Many companies see noticeable cost savings and reduced downtime within the first 6–12 months.

Q3: What types of machines can benefit from AI predictive maintenance?

Any machine with moving parts or electronics motors, pumps, belts, robotics, HVAC systems, etc. can benefit from predictive monitoring.

In the fast-paced world of manufacturing, time is money. Every minute of unplanned downtime can lead to lost productivity, missed…